2026 Author: Leah Sherlock | sherlock@quilt-patterns.com. Last modified: 2025-01-24 17:46:25

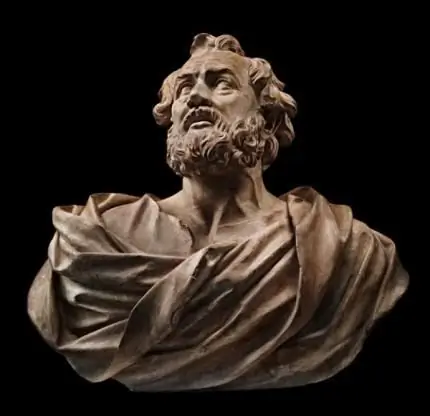

Bronze sculpture is part of the decor and a masterpiece of the master. As early as the 3rd millennium BC, bronze sculptures and vessels were made on the territory of Mesopotamia. The art form has survived to this day and, despite its antiquity, is very popular in the 21st century.

History of bronze items

In the beginning, ordinary tools and household items were made of bronze, and only a long time later they began to make works of art.

At first, tools were made using cold forging. But for the economy, such items turned out to be fragile. Tin was added to copper and a stronger metal, bronze, was obtained. It responded better to sharpening and proved to be much stronger.

Humanity developed and the method of hot casting was tried, which served as the start of the artistic production of products.

Bronze sculptures began to appear in the 5th century BC. They cast portraits of leaders, statues of the female body, figures of animals and birds.

Archaeologists are still discovering ancient exhibits, thanks to which knowledge of the past is expanding.

Antique bronze sculptures react in an interesting way to the flow of light rays. Bronze reflects light with clear sharp reflections. The main background of such products is based on the contrasts of appearance and distinct dark outlines.

Basic Features

For a sculptor, bronze is a substance that guarantees the durability of his work. Despite different weather conditions, bronze sculptures have been preserved for several centuries, which emphasizes its value:

- Oxidizing, the sculptures are covered with a thin coating called patina, and acquire a color from greenish to black.

- Bronze is interesting because it is an aesthetic material. All bronze figurines, sculptures, figurines are yellow-red or yellow-green. Items made from this material lend themselves well to toning, gilding and polishing.

- Bronze alloys are an expensive material, they minted coins, and jewelers made jewelry.

Bronze is not a pure metal, but with impurities. There are many different alloys of bronze.

Copper alloys

The alloys have different content of tin and copper. A typical modern bronze contains 88% copper and 12% tin. There is alpha bronze. It contains an alpha solid mixture of tin in copper. Such alloys are used for minting coins and mechanical parts.

History shows that when making their masterpieces, masters included other metals in a solution with copper. There were excellent connections. The bronze sculptures in the photo, which are presented in the article, evokeadmiration.

For example, Gloucester's candlestick. The bronze mixture is filled with zinc, tin, lead, nickel, antimony, arsenic, iron, and quite a hefty amount of silver. Most likely, the candlestick was made from old coins.

In the distant Bronze Age, different types of bronze were used to make products:

- Classic - 10% tin, slatted weapons were made.

- Moderate - 6% tin, ingots rolled into sheets, forged armor and helmets.

- Sculpted bronze - 90% copper and 10% tin, used to this day to create masterpieces.

Bronze is the most important material along with marble. But more masculine works are made from bronze, which convey strength and energy.

Sculpture casting

Bronze sculptures are still in great demand among we althy people and are considered a sign of good taste. The properties of bronze make it possible to produce large and small items, transferring even the smallest details.

Durable material that can be easily minted, cast and forged has been known since ancient Egypt. People knew how bronze sculptures were cast.

This is done in three ways:

- Casting mass into an empty mold. A very old method, they use it to prepare the most elementary figures. Bronze is poured into a hollow mold, left to set, and then removed.

- Piece casting (earth mold method). The method allowsuse the mold to pour bronze many times. It was in this way that sculptures were made in ancient Greece. This casting option was improved and is still used today. The sculpture is poured in separate elements, then assembled and processed.

- Casting with wax. A model of the future product is being prepared using gypsum, wood, and clay. The finished layout is covered with a special composition, and on top with silicone rubber. After 5-6 hours, the top layer hardens, and the lubricant allows it to be easily removed from the rubber mold, keeping all the smallest details intact. Next, the rubber form is combined with a solid one and filled with liquid wax. When it hardens, a wax copy of the product comes out. A sprue is attached to this copy, dipped in a ceramic solution, covered with stone powder and placed in an autoclave. After 10 minutes, the ceramic will harden and the wax will spread. Then, there is work with a ceramic form. Within two hours at a temperature of 850 degrees, it is fired and casting begins. An alloy of bronze, heated to 1140 degrees, is poured through the sprue into a ceramic mold. The alloy hardens after a short period of time. The mold is destroyed and the finished bronze sculpture is removed.

In addition to casting, a bronze statue can be hammered out of metal plates.

Embossing Sculpture

This type of manufacturing of bronze products is called repoussé. On fire, a sheet of metal is softened, with a hammer blow on the inside, the required bulge is given, gradually, blow by blow, the outlines and details of a masterpiece appear. The master must have a good background of practice anddexterity.

Tinting, patination and oxidation

On the surface of the bronze product, due to a certain chemical treatment, a colored protective coating is formed. If the bronze figurine is small, then it is dipped into a container with a solution in full. Large sculptures are subject to careful processing with a brush, foam rubber and a sponge. To fix the film on the product, and so that no plaque forms on it, after washing and drying procedures, rub it with a rag soaked in drying oil.

Now bronze products are regaining their popularity. In our time, you can find masterfully made figurines and figurines, in which the mood and every little thing is conveyed. They may well become part of a beautiful interior.

Recommended:

The actors of the film "The Good Guy": who are they and what roles did they play?

The actors of the film "The Good Guy" are well known to the general public, although they are not stars of the first magnitude. Starring: Alexis Bledel, Scott Porter, and Bryan Greenberg. Despite the fact that the film failed at the box office (budget: $3.2 million; box office: $100,368), it is still worth watching. An interesting plot and a brilliant game of actors will not leave you indifferent

Moscow Opera Houses. What are they and where are they located?

Acquaintance with opera for each person occurs at one time or another in life. It is impossible to foresee or force it, the understanding of this genre is a purely individual matter. When the soul begins to literally rush into the concert hall, all that remains for us is to find the right one. We will now briefly get acquainted with the opera houses of Moscow, and you can decide where it is better to go

Rodin sculptures: photo with description

French expression reflected in stone. A flight of fantasy, a moment that has stopped, a pronounced sensuality of the works. These are all sculptures by Rodin. Today we will talk about the work of this great artist, who made a huge contribution to world culture. In addition, he made a revolutionary breakthrough in sculpture. How? Read on and you will know

Renaissance sculptures: photo and description

During the heyday of the Renaissance in European society, there was an interest in antiquity. The most noticeable manifestation of the Renaissance culture was the "Renaissance" style in architecture. The foundations of architecture, formed over the centuries, were updated, often taking unexpected forms

Banderlogs: who are they and why are they needed

"Mowgli" is a very famous book by Kipling, which speaks in a language understandable to children about nobility and dignity, good and evil, and even such complex issues today as tradition and order