2026 Author: Leah Sherlock | sherlock@quilt-patterns.com. Last modified: 2025-01-24 17:46:27

Mineral paints of white color, made on the basis of lead, are named after the mineral that is part of them - white lead. Depending on the country, time and method of manufacture, lead-based paints were called differently: psimition, Dutch, cerussa, silver foam or simply silver, Klagenfurt, Venetian white, pure lead white, etc.

History of occurrence

For the first time white lead was described in the writings of the Greek writer Dioscorides as early as the 4th century BC. Even then they knew about the properties of lead and could produce paints from it. A little later, the technology for making whitewash, or, as they called them, cerussa, was already described by such Roman writers as Vitruvius, Pliny and Theophrastus. In the "new" world white lead first appeared in Holland already in the Middle Ages. Factory production of whitewash very quickly became widespread, and their consumption was constantly growing. Despite this, the scientist Bergman was able to reveal the chemical composition of white only by the end of the 18th century.

As for Russia, the history of the use and manufacture of white lead is not so ancient, only a hundred years ago they began to be produced here. Paint onlead-based is produced in large quantities in Yaroslavl, which is considered the center for the manufacture of whitewash. Today, there are several factories producing famous brands of white that are popular all over the world.

Scope of application

It is forbidden to use lead white as a solvent for other paints. The same applies to their use in painting work due to the high toxicity of the product. In exceptional cases, the use of lead-based white for metal surfaces is allowed.

If, nevertheless, lead white is used in work, then strict observance of the safety regulations prescribed in the case of using such preparations is necessary. Due to the harmful effects on the human body, even as an integral part of paints, it is forbidden to use lead white.

Due to the high toxicity, the use of whitewash is regulated at the legislative level. Thus, the laws of 1909 and 1926 affected the sharp decline in the annual production of these paints in France. Twelve paint and varnish factories in this country produced more than 20,000 tons of white a year, while at present the volume does not exceed 1,000 tons. These laws, unfortunately, apply only to France, in other countries the use of white lead is not limited by law.

Properties of white lead

They are produced as a white heavy powder with a granular structure. When exposed to vaporacetic acid to lead and white lead is formed. Their color, as the name suggests, is white. Due to the nature of the manufacturing process, the finished product contains a small amount of lead sugar. This affects the smell of white lead, they have a slightly sour aroma, and the ratio of the main acetic lead s alt should not exceed 1% of the total impurities.

Mineral paints, which contain white lead, have high hiding power and a short drying time. Up to 10% of the total weight of paints is their oil absorption. In the open air, the white hardens very quickly, and this occurs throughout the entire thickness of the paint layer. It is thanks to this quality that lead white is so in demand in painting in multi-layer technique and in the production of oil ground coatings.

The composition and, consequently, the ability to dry quickly, these paints are easily transferred to other materials, as a result of which even slow-drying paints dry quickly throughout their entire layer. They have gained particular value for underpainting, as they are ideal for subsequent staining, while they bond well with subsequent layers and do not crack.

Cons of using white lead

Along with the obvious advantages of using white lead, they have a number of significant disadvantages.

First of all, it is worth noting the high toxicity of the powder. When grinding, all safety rules must be observed so that the powder is not sprayed. Known not onlycases of severe poisoning, but also deaths.

Lead white is able to change its light. When the paint is exposed to hydrogen sulfide, it first begins to turn brown, and then completely turns black. This happens only if there is not enough binder in the composition of the white. However, this process is reversible. To acquire a painted surface of its original appearance, it is necessary to treat the paint with hydrogen peroxide, which can convert black lead sulfide into white sulfide.

In an alkaline environment, white is very unstable, which is why they are not suitable for alkaline tempera and frescoes.

Such specificity was noticed in painting. Lead white ground with linseed oil has the ability to change light. If the picture is turned away from the window and directed towards the wall, the paint based on white lead turns yellow, but is able to return to its original color if it is exposed to direct sunlight for a while.

Variety of whitewash

Today, various types of white are used. Lead, zinc and titanium are the most common.

Lead - the most ancient, they are most often used by old artists. Their advantage is that you can apply transparent layers, and the paint dries very quickly. It has a flexible structure and is more resistant. But the main disadvantage is its toxicity.

Titanium white. They are no less popular with artists and are similar in characteristics to white lead. This color tonethe whitest, but its minus is that it is absolutely opaque and completely paints over other tones.

This white is very popular with potters. They intervene directly into the clay, and if this is not enough, then they are applied on top with a thin layer.

Zinc white. They are not as thick as titanium white and therefore they are used for tinting and applying transparent layers. The downside of this paint is only a long drying time.

Dutch way

This is the very first and oldest method of extracting white lead. For this method, lead plates 2-3 mm wide are cut into strips up to 6 cm long and placed in glazed earthenware pots, while coiling. Pots should be about 1 liter, and not exceed 20 cm in height. 250 ml of vinegar is also poured there. The pots are placed in rows in brick chambers and, sprinkled with layers of horse manure, are stacked. A layer of horse manure is covered at the bottom, the first layer of pots is set on it, from above they are covered with lead plates and boards, and the gaps between the pots are also filled with manure. In this way, the pots are installed in layers to the very top.

During the fermentation of manure, heat is released, which contributes to the evaporation of acetic acid. When oxygen is catalyzed from the air, an acetic lead s alt is formed, which is converted into carbon lead, which is white lead. The process of separating white from lead plates is the most painstaking, most often done by machines. The most used for thesetargets is a Horn device.

German way

The difference between the German way and the Dutch way is only in the details. Lead sheets are not placed in pots, but are hung in brick and wooden chambers. And then the process of exposure to acetic acid and oxygen is identical. Most often, Major's device is used for this method.

French way

Tenar proposed a French method for making white lead. For him, first, a solution of acetic lead s alt is made, through which carbon dioxide is then passed. As a result, white is released, and the average acetic lead s alt remains in solution. This method is continuous, since the litharge is dissolved again in the spent solution, forming the main s alt.

English way

This method of extracting white lead is more complex, and that is why it has been used less and less lately. A litharge moistened with a 1% solution of lead sugar is placed in horizontal drums. There he rotates with the help of stirrers. At the same time, it is processed with a jet of carbon dioxide.

For this method, it is extremely important that there are no impurities in the litharge, otherwise the white may acquire an undesirable shade.

Recommended:

Monuments in St. Petersburg: names and photos. Workshops for the manufacture of monuments in St. Petersburg

St. Petersburg (St. Petersburg) is the second largest metropolis in the Russian Federation after Moscow. From 1712 to 1918 it was the capital of Russia. It is considered one of the most beautiful cities in the world. In this article, we will consider the most famous monuments of St. Petersburg

Whomping willow: description, magical properties and role in the story of Harry Potter

Has anyone seen a more unusual, mysterious and at the same time aggressive magical tree? Professor Snow claimed that this is the rarest specimen of the weeping willow subspecies of the wizarding world of Harry Potter. What does the rattling willow hide in itself and why was such a vicious plant planted on the territory of a magical school?

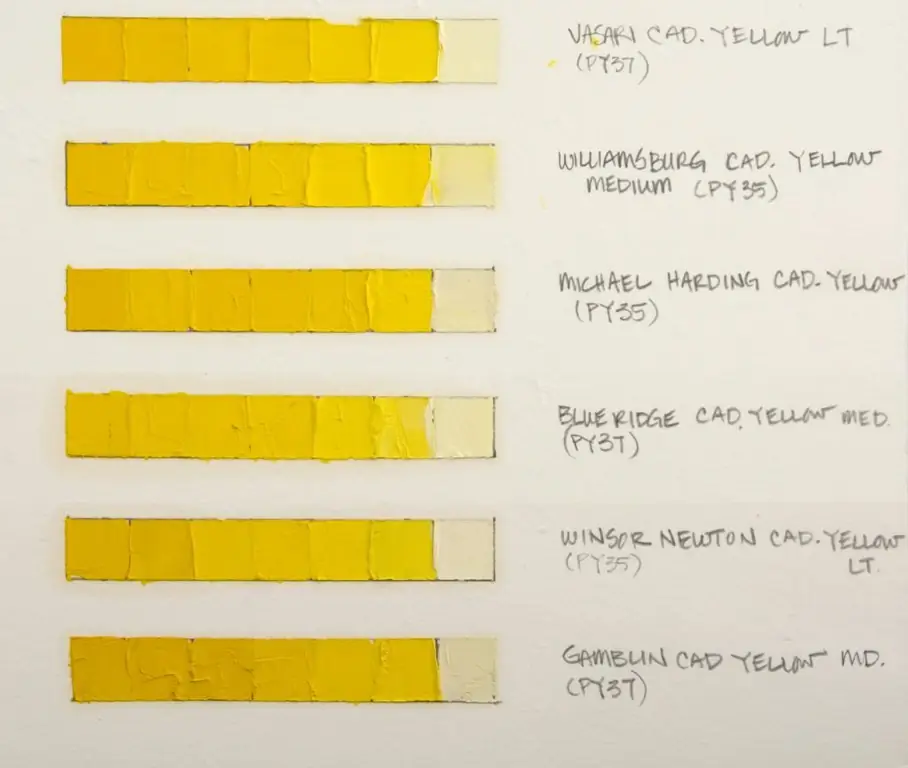

Yellow cadmium for oil painting: properties and obtaining paints

Cadmium - natural and artificial. Chemical properties of yellow cadmium. How paint is obtained in production - dry and wet methods. Features a light shade - bright lemon. Features midtones, dark (orange) cadmium

What is gouache: composition, properties and types, application features

All children and many adults love to draw. Before you start the creative process, you should understand what gouache is. Firstly, this word refers to the paint itself. The second answer to the question, what is gouache, will be as follows: these are the drawings made by her. How to make gouache at home and what drawing techniques exist, you can learn from this article

Canvas is: description, properties, application, types and features

Painting is a popular activity available today not only to professional artists, but also to amateurs. Every painting starts with a base. Canvas is a wonderful basis for a painting